Call Us: (+381) 63 650-532Contact us:sales@mashtronics.com

Industrial Mesh & Wire Products

Industrial Mesh & Wire Products

If you need mesh panels, 2D, 3D, or 4D fences, gabions or stone baskets, cable trays, animal cages, and more, our wire processing systems deliver the perfect solution.

Our wire processing systems are designed for precision and flexibility, adapting to your specific requirements to ensure high-quality results across a wide range of industrial applications.

Our wire processing systems are designed for precision and flexibility, adapting to your specific requirements to ensure high-quality results across a wide range of industrial applications.

Do you need additional information?

End Applications

Fences

From 3D panels with reinforcements and anti-climb security fences to double wire meshes, mobile fence panels, or roll fencing – our fence mesh welding machines are designed to deliver efficient and cost-effective production across both small and large series.

Depending on the chosen system, wires can either be automatically straightened and cut within the machine or fed directly from spools, coils, or reels, ensuring maximum flexibility for different production needs.

Depending on the chosen system, wires can either be automatically straightened and cut within the machine or fed directly from spools, coils, or reels, ensuring maximum flexibility for different production needs.

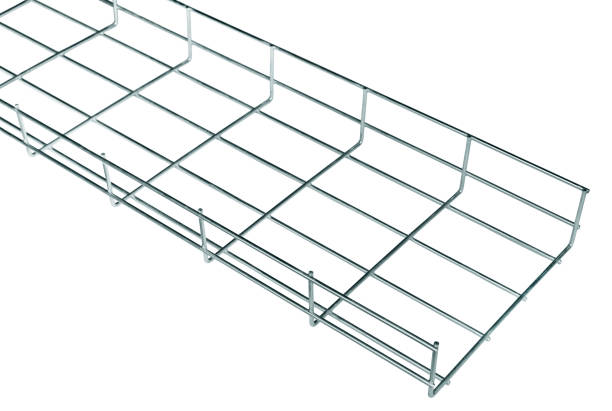

Cable Trays

Manufacturing reliable cable trays requires advanced technology and a well-structured process. Our machines are designed to handle every stage of production – from wire preparation and accurate straightening to cutting and welding – with outstanding precision.

Depending on your needs, we can integrate additional operations such as T-welding, trimming, embossing, bending, or automated stacking.

Whether producing from coil or bar, in single-line or multi-line setups, our systems combine speed, flexibility, and quality to deliver both high-volume output and tailor-made solutions with minimal lead times.

Depending on your needs, we can integrate additional operations such as T-welding, trimming, embossing, bending, or automated stacking.

Whether producing from coil or bar, in single-line or multi-line setups, our systems combine speed, flexibility, and quality to deliver both high-volume output and tailor-made solutions with minimal lead times.

Deckmesh

Deckmesh is a versatile shelving option, designed for heavy-duty use in warehouses and logistics centers. Its strength lies in a stable steel wire construction, usually treated with galvanization or powder coating for superior durability.

The lightweight, open-grid design prevents the buildup of dust and liquids, while also ensuring easy visibility of pallets and stored products.

With Mashtronics welding technology and a high degree of automation, we can manufacture virtually any deck mesh design quickly and precisely.

From flat bar supports to V or U profiles, folded or raised edges, internal reinforcements, or edge-free versions – every solution can be customized to match your requirements.

The lightweight, open-grid design prevents the buildup of dust and liquids, while also ensuring easy visibility of pallets and stored products.

With Mashtronics welding technology and a high degree of automation, we can manufacture virtually any deck mesh design quickly and precisely.

From flat bar supports to V or U profiles, folded or raised edges, internal reinforcements, or edge-free versions – every solution can be customized to match your requirements.

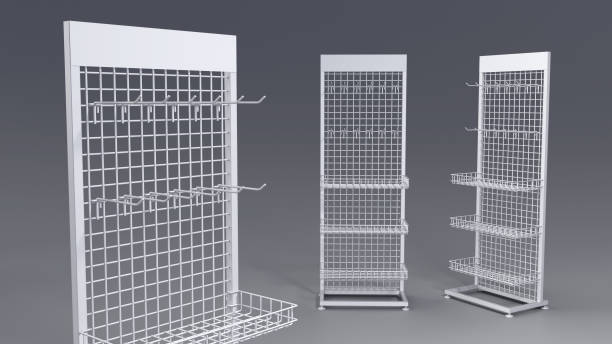

Shopfitting

Wire mesh plays a key role in modern shopfitting, offering a combination of durability, practicality, and aesthetic appeal.

Its modular nature allows it to be easily adapted to the unique requirements of any retail environment.

Beyond standard designs, customized wire mesh solutions are often needed – with variations in mesh size, wire thickness, or specialized mounting systems.

To produce both standard and bespoke shopfitting meshes efficiently, a highly flexible and powerful manufacturing system is essential.

Such a system must ensure fast changeovers and be capable of processing materials like steel, stainless steel, flat bars, and frame structures with precision and consistency.

Its modular nature allows it to be easily adapted to the unique requirements of any retail environment.

Beyond standard designs, customized wire mesh solutions are often needed – with variations in mesh size, wire thickness, or specialized mounting systems.

To produce both standard and bespoke shopfitting meshes efficiently, a highly flexible and powerful manufacturing system is essential.

Such a system must ensure fast changeovers and be capable of processing materials like steel, stainless steel, flat bars, and frame structures with precision and consistency.

Machine fencing / Room dividers

Welded wire mesh is a practical choice for machine guarding and room dividers, providing both safety and versatility in industrial settings.

Its sturdy and long-lasting construction makes it a cost-effective solution for organizing and protecting work areas.

With Mashtronics equipment, you can achieve fast, high-volume production as well as flexible customization for unique designs – all while maintaining exceptional quality and short lead times.

Its sturdy and long-lasting construction makes it a cost-effective solution for organizing and protecting work areas.

With Mashtronics equipment, you can achieve fast, high-volume production as well as flexible customization for unique designs – all while maintaining exceptional quality and short lead times.

Gabion grids, Stone baskets

Producing gabion meshes and stone baskets demands not only precision, premium materials, and efficient processes, but also exceptionally strong and consistent welded connections.

With our modular machine concept, you can begin with a cost-effective basic setup and expand it step by step.

By adding various modules and automation options, the system can evolve into a fully automated production line that requires minimal manual intervention.

With our modular machine concept, you can begin with a cost-effective basic setup and expand it step by step.

By adding various modules and automation options, the system can evolve into a fully automated production line that requires minimal manual intervention.

Ovens and Refrigerators grills

Grilles for ovens, grills, and refrigerators must withstand extreme temperature conditions, making strong welded joints and high-quality materials essential for durability, safety, and performance.

Our reliable mesh welding systems support efficient production, ranging from semi-automatic to fully automated processes, primarily focusing on large-scale manufacturing of rectangular mesh patterns.

Additionally, a variety of modular options—including the widely used T-welding unit—enable tailored configurations to meet specific customer needs.

Our reliable mesh welding systems support efficient production, ranging from semi-automatic to fully automated processes, primarily focusing on large-scale manufacturing of rectangular mesh patterns.

Additionally, a variety of modular options—including the widely used T-welding unit—enable tailored configurations to meet specific customer needs.

Animal cages

Animal cages are typically constructed from thin, galvanized wire featuring small mesh openings.

The main manufacturing challenges include ensuring welds that are both strong enough to protect the animals and durable for long-term use, while also producing a flat, distortion-free mesh without sharp edges or corners.

Utilizing targeted welding groups and advanced MF welding technology, we focus the energy precisely on each weld point.

This approach reduces heat impact on the mesh, resulting in a smooth, flat grid with consistently high-quality, reliable welds.

The main manufacturing challenges include ensuring welds that are both strong enough to protect the animals and durable for long-term use, while also producing a flat, distortion-free mesh without sharp edges or corners.

Utilizing targeted welding groups and advanced MF welding technology, we focus the energy precisely on each weld point.

This approach reduces heat impact on the mesh, resulting in a smooth, flat grid with consistently high-quality, reliable welds.

Mine grids

In mining operations, welded mine grids are vital for protecting workers in shafts, tunnels, and galleries from potential collapses and landslides, while also enhancing the structural stability of mining facilities.

Due to the high safety standards involved, consistently strong and secure welded joints are essential.

Mashtronics provides reliable welding technology alongside a variety of coil and rod systems that enable efficient and cost-effective production of these critical grids.

Due to the high safety standards involved, consistently strong and secure welded joints are essential.

Mashtronics provides reliable welding technology alongside a variety of coil and rod systems that enable efficient and cost-effective production of these critical grids.

SERBIA

Headquarters

We are located in Mladenovac, only 45 km away from the capital Belgrade.