Call Us: (+381) 63 650-532Contact us:sales@mashtronics.com

Steel Wires

Steel Wires

Our wire drawing machines are engineered for processing drawn wire, bare wire and ribbed wire with precision and efficiency.

Designed for reliable operation and long service life, they deliver consistent results in steel wire production.

Designed for reliable operation and long service life, they deliver consistent results in steel wire production.

Do you need additional information?

End Applications

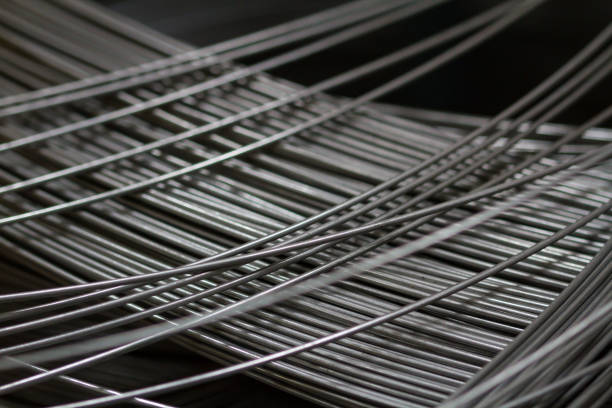

Bare Wire

Bright steel wire is manufactured through cold drawing of wire rod, which improves its mechanical properties and creates a smooth surface with precise dimensional tolerances.

The drawing process enhances the wire’s strength, and the number of drawing stages depends on the starting and final diameters, wire grade, and required reduction.

Mashtronics wire drawing machines are suitable for processing wires with small to medium diameters and it can draw low, medium and high carbon wire.

This type of wire is commonly used in industrial applications, including nails, galvanized wire, and wire ties.

After drawing, the wire can be coiled on spools or collected on vertical carriers, depending on customer requirements.

The drawing process enhances the wire’s strength, and the number of drawing stages depends on the starting and final diameters, wire grade, and required reduction.

Mashtronics wire drawing machines are suitable for processing wires with small to medium diameters and it can draw low, medium and high carbon wire.

This type of wire is commonly used in industrial applications, including nails, galvanized wire, and wire ties.

After drawing, the wire can be coiled on spools or collected on vertical carriers, depending on customer requirements.

Ribbed Steel Wire

Ribbed steel wire is primarily used to manufacture reinforcement components that provide enhanced adhesion in concrete structures, such as reinforcing meshes, cages, and stirrups.

This wire is produced by cold forming bare steel wire, where longitudinal and transverse ribs are created through precision cold rolling.

These ribs improve the mechanical grip within concrete, ensuring structural stability. Our cold rolling lines feature modular designs and versatile configurations, enabling efficient production of both coils and spools, as well as automated straightened bars.

The automation level can be tailored to meet the specific production needs of each client.

This wire is produced by cold forming bare steel wire, where longitudinal and transverse ribs are created through precision cold rolling.

These ribs improve the mechanical grip within concrete, ensuring structural stability. Our cold rolling lines feature modular designs and versatile configurations, enabling efficient production of both coils and spools, as well as automated straightened bars.

The automation level can be tailored to meet the specific production needs of each client.

Nails

Steel nails are widely used in construction, woodworking, furniture manufacturing, and various industrial applications.

They are typically made from low or medium carbon steel wire, which is drawn and processed to achieve the required hardness and strength.

The surface of the nails can be plain, galvanized, or coated to increase corrosion resistance, depending on the intended use.

They are typically made from low or medium carbon steel wire, which is drawn and processed to achieve the required hardness and strength.

The surface of the nails can be plain, galvanized, or coated to increase corrosion resistance, depending on the intended use.

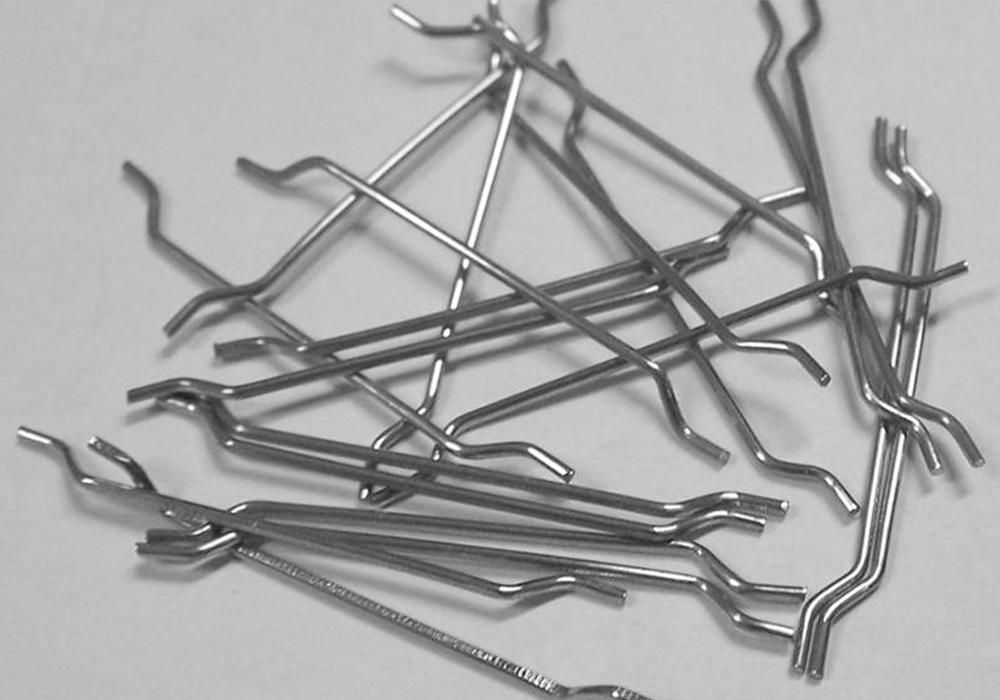

Steel Fibers

Steel fibers are increasingly used as an effective reinforcement solution in concrete construction.

These small, high-strength fibers are incorporated directly into the concrete mix to improve its mechanical properties, including crack resistance, impact durability, and overall toughness.

They are widely applied in industrial floors, bridges, tunnels, and precast elements, providing better load distribution and a longer service life for concrete structures.

These small, high-strength fibers are incorporated directly into the concrete mix to improve its mechanical properties, including crack resistance, impact durability, and overall toughness.

They are widely applied in industrial floors, bridges, tunnels, and precast elements, providing better load distribution and a longer service life for concrete structures.

SERBIA

Headquarters

We are located in Mladenovac, only 45 km away from the capital Belgrade.